TSUKUBA, Japan, March 22, 2021 /PRNewswire/ -- A research team at WPI-MANA has developed a surprisingly simple method for fabricating highly organized mono- and multilayers of 2D nanosheets. All one needs to do the job is a pipette and a hotplate.

Two-dimensional nanosheets have been generating a lot of excitement worldwide recently. Their broad range of unique electronic, magnetic, optical and thermal properties could find their way into next-generation devices. However, further development of 2D materials depends on finding deposition processes that enable precise layer-by-layer control of thin films while reducing time, cost and energy/sample consumption.

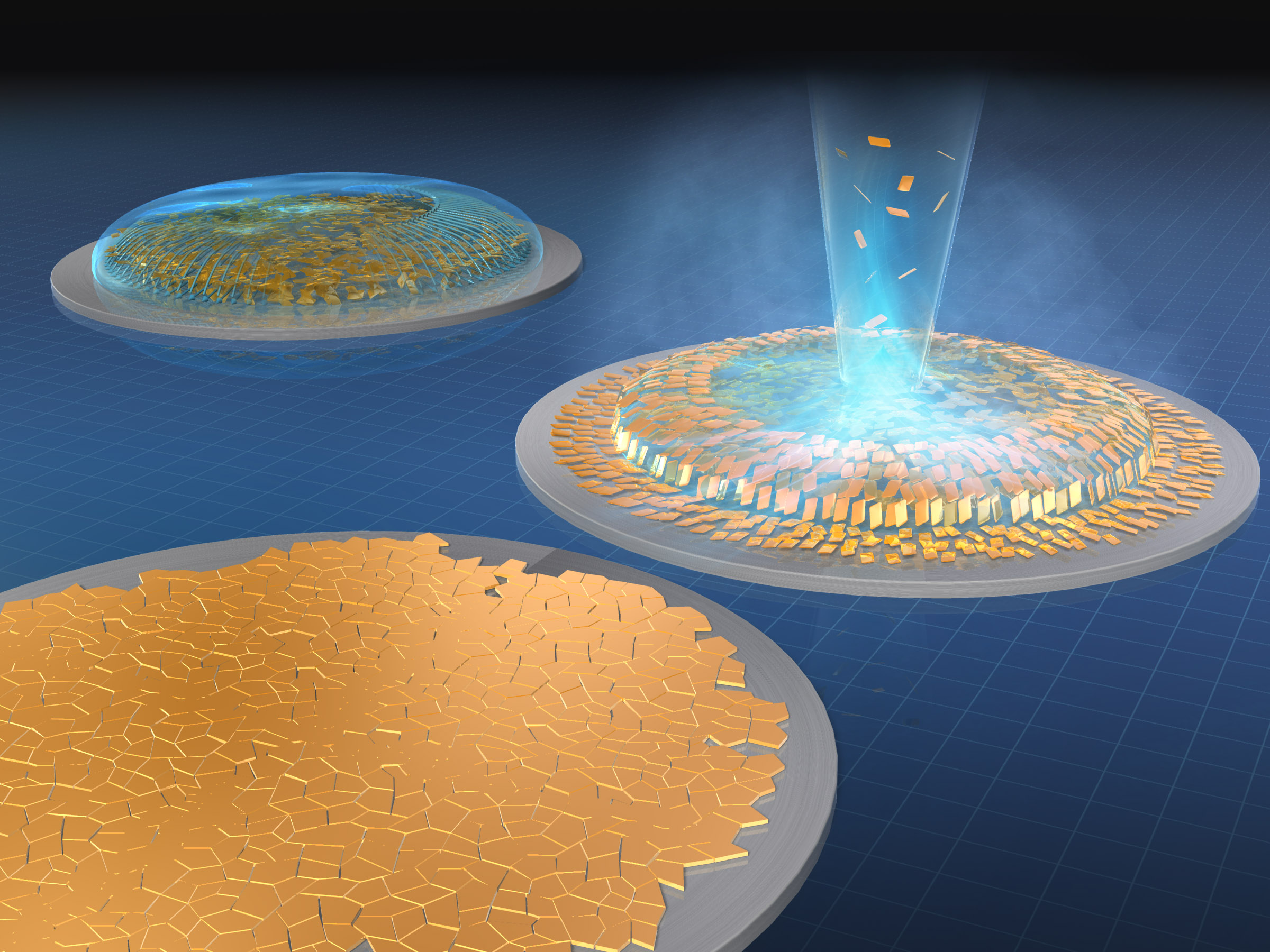

The team found that a simple one-drop approach improves "drop casting" fabrication of tiled nanosheets. Drop casting is one of the most versatile and cost-effective methods of depositing nanomaterials on solid surfaces. But it has serious drawbacks, including the so-called coffee-ring effect, a pattern left by particles after the liquid evaporates.

They found, to their surprise, that controlled convection by a pipette and a hotplate causes uniform deposition rather than a ring-like pattern, suggesting a new possibility for drop casting. The process is surprisingly simple -- dropping a solution containing 2D nanosheets with a simple pipette onto a substrate heated on a hotplate, followed by removal of the solution, causes the nanosheets to come together in about 30 seconds to form a tile-like layer.

The team also produced various functional coatings such as conducting, semiconducting, insulating, magnetic and photochromic coatings in multilayer, superlattice and submicrometer-thick forms, which showed the potential for a convenient way to produce high-quality 2D nanosheet films. If the process can be scaled up, it could advance development of next-generation electronics.

This research was carried out by Minoru Osada (NIMS Invited Researcher, Soft Chemistry Group, WPI-MANA, NIMS) and his collaborators.

"Single Droplet Assembly for Two-Dimensional Nanosheet Tiling" Yue Shi et al., ACS Nano (October 29, 2020)https://doi.org/10.1021/acsnano.0c05434

MANA E-BULLETINhttps://www.nims.go.jp/mana/ebulletin/